Dorman Long Technology

Construction Equipment

Construction Engineering

Site Support Services

- Home

- Products

- Construction Engineering

- Site Support Services

- Reference Projects

- Careers

- Contact Us

We develop, manufacture and operate the specialist technology for modular construction of bridges, dams, refineries, power stations, offshore structures, buildings and manufacturing plants. We also offer construction engineering and site services to help our clients get the best value from the equipment we supply.

Our role on most projects is to develop solutions to construction problems, fully engineer these solutions and then to work with our customers to carry out the operations on site. We are happy to offer any combination of erection engineering, equipment supply / rental and site supervision services to suit the needs of each project.

Our product range includes bridge construction equipment, offshore construction equipment, jacking tower systems, strand jacks, hydraulic gantries, skidding systems and synchronised jacking and weighing systems. Please click on the 'Products' link above for the full list of our products, and also click on the 'Reference Projects' link above to see many examples of our products and services in use.

All our projects are covered by our company management systems, which are accredited to ISO 9001: 2008 , OHSAS 18001:2007 and ISO 14001: 2004. All these management systems have been written in-house by our own staff to ensure total relevance to our business. Read more »

Dorman Long and Co. Ltd was originally formed in 1875 and we have a page of useful links and resources for anyone interested in finding out more about the history of our famous company.

Read more »

October 2015

The DL-TS3600 jacking tower system has been successfully load tested to 125% of rated capacity.

Read more » First deck unit lifted, Queensferry Crossing, UK

September 2015

The first deck unit on the Queensferry Crossing cable stay bridge has been lifted into place using DLT designed deck erection gantries.

Read more » New Champlain Bridge Project, Montreal, Canada.

August 2015

DLT awarded contract for supply of a 1000 tonne capacity self propelled transporter and a synchronised jack up system for handling precast concrete bridge sections.

Read more » Margaret McDermott Bridge, Dallas.

August 2015

American Bridge lift a 95 m long 200 tonne arch centre section using DLT strand jacks and computer control system.

Video » Temburong Bridge Project, Brunei.

July 2015

DLT awarded the contract to design and supply a bridge deck erection gantry to simultaneously erect two 50m long 870 tonne precast concrete deck girders

Read more » 360 tonne generator installation, India.

June 2015

Lift & Shift India have installed their first generator using a new installation gantry designed and supplied by DLT

Read more » Riyadh Metro project, Saudi Arabia.

May 2015

First bridge beam erected on site.

Read more » Sheikh Jaber Al Ahmed Al Sabah Causeway Project,

Doha Link, Kuwait

January 2015

DLT awarded the contract for detailed design of a bridge deck erection gantry (launching girder), self propelled transporter and straddle carriers for handling 1700 tonne x 60m span precast bridge beams.

Read more » Riyadh Metro project award, Saudi Arabia

January 2015

DLT have been awarded the contract to design and supply a second set of DL-SE500/35 bridge deck erection gantry (launching gantry) and DL-TLC500 self propelled transporter plus 2 No 260 tonne straddle carriers for transport and erection of 500 tonne x 35m long precast concrete bridge beams on the Riyadh Metro project, by client FAST Consortium.

Read more » MYQ5000 tower system successfully load tested, China

December 2014

The MYQ5000 jacking tower system has been successfully load tested to 125% capacity.

Read more » 1200 tonne bridge lifts, Zambia

May 2014

Vanguard have successfully erected two 1200 tonne steel bridges in Zambia using four DL-S418 strand jacks supplied by DLT. Congratulations to Vanguard for a job well done!

Read more » 3600 te capacity weighing system delivered, Vietnam

April 2014

An 8 jack, 3600 te capacity weighing system was delivered, commissioned and used for the first time by client PTSC

Read more » Riyadh Metro project award, Saudi Arabia

March 2014

DLT have been awarded the contract to design and supply a DL-SE500/35 bridge deck erection gantry (launching gantry) and a DL-TLC500 self propelled transporter for transport and erection of 500 tonne x 35m long precast concrete bridge beams on the Riyadh Metro project, by client FAST Consortium.

Read more » MYQ4000 tower system award, China

March 2014

DLT have been awarded the contract to design a 4000 te lifting capacity jacking tower system to Sinopec No 4 construction company in China

DL-TS3600 tower system award, China

Sept 2013

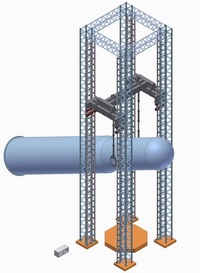

DLT have been awarded the contract to design and supply a 7200 te lifting capacity jacking tower system to China

Read more » MYQ5000 tower system award, China

June 2013

DLT have been awarded the contract to design and supply a 5000 te lifting capacity jacking tower system to China

Read more » Double topside float over, India

Jan 2013

DLT supplied float over jacking system installs 13,400 te & 7,000 te topsides

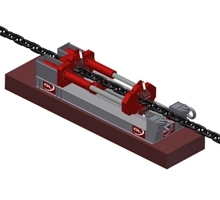

Read more » 2 No DL-GP1000 skidding units delivered to Nippon Steel

Mar 2013

DLT supplied 2 No 1000 push-pull skidding units to Nippon Steel for load out and installation of offshore jackets

Read more » Stadium cable net roof erected, Brazil

Dec 2012

The Brasilia stadium cable net roof is erected using a DLT supplied 48 point computer controlled strand jack system

Read more » Calvary Convention Centre, Malaysia

Sept 2012

A 16 point computer controlled jacking system is installed to open and close two large roof panels

Read more »

We offer a range of construction engineering consultancy services for the design and construction of many types of structure, including bridges, buildings, heavy process plant, petrochemical vessels and offshore structures. We have particular expertise in the erection of long span suspension and cable stayed bridges, and in the engineering of specialist modular construction operations such as heavy lifting, lowering and horizontal skidding operations.

Our engineers draw on first-hand experience of site operations to provide practical schemes supported by clear and concise documentation. We can develop schemes from initial concept through to detailed design including stage by stage analysis of the permanent works if required

All consultancy

services are provided under our ISO 9001:2008 accredited quality management system and covered by professional indemnity insurance.

Our services include the design of the following :

- Heavy lifting operations

- Skidding operations

- Mechanised temporary works

- Bridge deck erection gantries

- Bridge deck launching and sliding

- Power station heavy plant installation

- Erection of large roof structures

- Long span bridge erection engineering, including cable stayed and suspension bridges

- Modular steel bridges, including cable stayed and suspension bridges

We also offer 3rd party independent checking services for construction methods and temporary works designs for projects on a global basis. For example in the UK we have experience in certifying projects for clients Network Rail and the Highways Agency

Site Support for our equipment is provided by our Site Technicians, who have many years of experience of carrying out heavy lifting operations and will usually be seconded into a client's team to assist with the first few operations until the client's own staff feel confident to operate the equipment themselves. As part of this service we provide a formal training and certification programme to approve client's staff as competent to operate and maintain the equipment. Our Site Technicians become a valued member of the site team and are usually requested to return to assist with future operations.

Our Site Technicians are also available to carry out periodic maintenance and load testing of the equipment with manufacturer’s certification of the work carried out.

We maintain a stock of strand jacks for rental or quick delivery, to enable us to respond rapidly to the needs of each project

The following projects are examples of our involvement in the engineering, equipment supply and operations on site. The highlighted projects demonstrate the full range of our work. Lists of example projects for each sector can be viewed by clicking on the tabs on the left of the page.

- > Highlights

- > Bridge projects

- > Oil and Gas

- > Power projects

- > Building projects

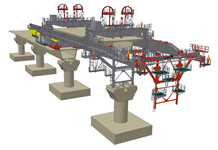

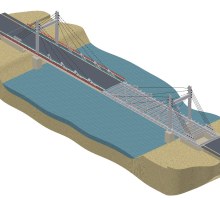

In July 2015 DLT were awarded a contract by main contractor Daelim-Swee to design and supply a 2 x 870 tonne capacity bridge deck erection gantry for the Temburong Bridge Project. The gantry will be used to simultaneously erect two 50m long 870 tonne precast concrete bridge beams for the 13.65 km length of marine viaduct on the project. The gantry will be delivered in April 2016 and is expected to be in operation on the project for 2 years.

Read more»

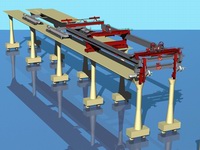

In 2015 we carried out the detailed design of a bridge deck erection gantry, a transporter and a pair of straddle carriers for the handling of precast concrete bridge deck beams weighing up to 1700 tonnes and with spans varying from 30m to 60m.

Read more»

In August 2015 DLT were awarded the contract to design and supply a compact 1000 tonne capacity self propelled transporter to handle large precast concrete sections of the bridge foundations and piers.

Read more»

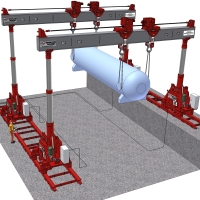

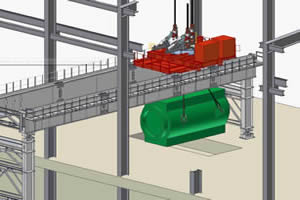

In June 2015 Lift and Shift India installed their first generator using a 540 tonne capacity modular gantry designed and supplied by DLT. The gantry is modular to accommodate the geometry of each site and incorporates folding strand jacks to reduce the headroom requirement as the generator is moved into the turbine hall and under the overhead crane rail. The gantry is able to lift, rotate and move the generator into final position and incorporates both transverse and longitudinal movement systems to allow the generator to be set accurately onto its foundations.

Read more»

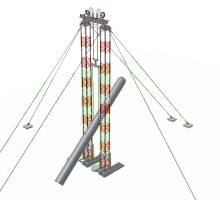

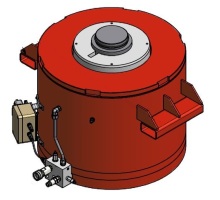

In 2014 we designed and supplied a 5,000 tonne lifting capacity jacking tower system to China National Petroleum (CNPCC) for use in the erection of heavy petrochemical vessels. The MYQ5000 jacking tower system is able to self-erect and self-dismantle, and is also able to move with the vessel after lifting. The MYQ5000 was successfully load tested in December 2014 and is expected to complete its first project in China in 2015.

Read more»

DLT are suppliers of 2 No 500 tonne capacity deck erection gantries, 2 No 500 tonne transporters and 2 No 260 tonne x 25m high straddle carriers to Main Contractor FAST Consortium. The system will be delivered in 2015.

Read more»

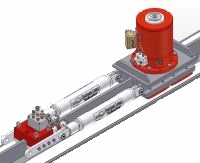

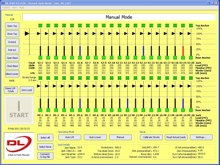

DLT supplied an eight jack 3600 MT capacity weighing system to PTSC Vietnam in April 2014. The weighing system incorporates load cells for a load accuracy of 0.5% and has a central computer control system for synchronised lifting and lowering of the load and for data logging throughout the weighing operation.

Read more»

DLT supplied a 48 x 98 tonne computer controlled strand jack system to Protende in Brazil for the erection of a cable net roof structure on the Brasilia stadium, constructed to host the 2014 world cup.

Read more»

DLT supplied two complete float over jacking systems to Swiber Offshore Construction for the offshore installation of platforms weighing up to 13,400 tonnes in the ONGC B-193 process complex in the Arabian Sea.

Read more»

DLT were sub-contractors to Samsung C&T for design and supply of a DL-SE1000/35 span erection gantry for erecting the full length of section 4-1 on the Honam High Speed Railway project in Korea. The DL-SE1000/35 can erect precast spans weighing up to 1000 tonnes and up to 35m long at a rate of up to 2 spans per day and is self launching into the next span.

Read more»

DLT were responsible for the detailed erection engineering for the 26,000 tonnes of structural steel, including stands, cable suspended roof and main arch structures. The 1,490 tonne main arch was assembled flat and rolled up into position using strand jacks. We were responsible for engineering and supervising this operation.

Read more»

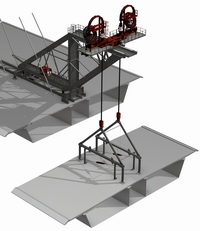

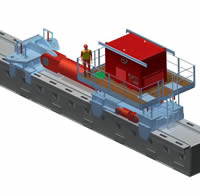

The Olmsted Locks and Dams project consists of twin 110-foot wide by 1,200 foot long lock chambers on the Ohio river at Olmsted, Illinois. The lock chambers are constructed from heavy precast concrete units, that will be cast in a yard on shore and then handled on land using a purpose made gantry crane and in the water using a purpose made heavy lift catamaran barge. DLT were awarded the contract to design, supply and operate 2 No 12,000 tonne capacity computer controlled strand jack systems for use as the main lifting systems on both the gantry crane and the catamaran barge.

Read more»

With a main span of 1088m the Sutong Cable stayed bridge was the longest span cable stayed bridge in the world when completed. DLT were sub-contractors to 2nd Navigation Engineering Bureau for the design, supply and operation of the eight deck erection gantries that were used to erect the 84 No steel orthotropic deck segments, each weighing up to 450 tonnes, between 9th November 2006 and 9th June 2007.

Read more»

These gantries have since been used to erect the decks on two further bridges in China, the shanghai-Yangtze cable stayed bridge and the E-Dong cable stayed bridge.

On the Sutong bridge, we were also responsible for lowering of a 3050 tonne caisson.

Read more»

DLT were sub-contractors for installation of a new 40.75m high 3115 tonne furnace line in Taiwan. Our scope included full engineering of all temporary works required together with supply of jacking equipment and site labour to carry out the work. The blast furnace was delivered to the site in 8 segments, weighing up to 477 tonnes each, which were lifted and skidded into the furnace house before being jacked vertically and aligned for welding. These operations were carried out using a mix of strand jacks and climbing jacks.

Read more»

DLT were responsible for the design, supply and commissioning of 4 No 370 tonne capacity deck erection gantries for this 1490m main span suspension bridge. The gantries were designed to walk the main cables and work in pairs to erect steel deck units weighing up to 470 tonnes each. The gantries can be self erected onto the main cables and can be easily adapted for future projects with different cable centres and diameter.

Read more»

In July 2015 DLT were awarded a contract by main contractor Daelim-Swee to design and supply a 2 x 870 tonne capacity bridge deck erection gantry for the Temburong Bridge Project. The gantry will be used to simultaneously erect two 50m long 870 tonne precast concrete bridge beams for the 13.65 km length of marine viaduct on the project. The gantry will be delivered in April 2016 and is expected to be in operation on the project for 2 years.

Read more»

In August 2015 DLT were awarded the contract to design and supply a compact 1000 tonne capacity self propelled transporter to handle large precast concrete sections of the bridge foundations and piers.

Read more»

In 2015 we carried out the detailed design of a bridge deck erection gantry, a transporter and a pair of straddle carriers for the handling of precast concrete bridge deck beams weighing up to 1700 tonnes and with spans varying from 30m to 60m.

Read more»

DLT are suppliers of 2 No 500 tonne capacity deck erection gantries, 2 No 500 tonne transporters and 2 No 260 tonne x 25m high straddle carriers to Main Contractor FAST Consortium. The system will be delivered in 2015.

Read more»

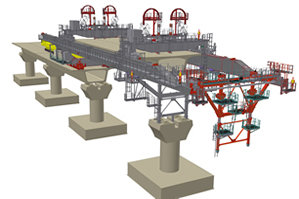

DLT are appointed by the Main Contractor, Forth Crossing Bridge Constructors, as construction engineers for the launching of the North Approach Viaduct and for the design of the deck erection gantries for the cable stayed spans. The North Approach Viaduct launch section will be 221m long and weigh 4200 tonnes. It will will be launched a distance of 233m. There will be 6 No deck erection gantries which will be used to erect a total of 109 steel/concrete deck sections weighing up to 729 tonnes at an erection rate of 1 section per gantry per week.

Read more»

In February 2011 the 1000 tonne Ponte Verde steel arch bridge was launched into position by Edimo Metallo S.p.A. using DLT strand jacks and site supervision.

Read more»

DLT were sub-contractors to Samsung C&T for design and supply of a DL-SE1000/35 span erection gantry for erecting the full length of section 4-1 on the Honam High Speed Railway project in Korea. The DL-SE1000/35 can erect precast spans weighing up to 1000 tonnes and up to 35m long at a rate of up to 2 spans per day and is self launching into the next span.

Read more»

The Ponte Sobre O Rio Negro is a 3505m long crossing of the Rio Negro in the heart of the Amazon rain forest, linking Manaus with Iranduba over the river Negro. DLT were awarded the contract to design, supply and operate 2 No 320 tonne capacity deck erection gantries to handle the 52 precast concrete deck sections of the cable stayed span.

Read more»

The E-Dong Cable Stayed Bridge is located in Huanggang city, Hubei Province, China, and crosses the Changjiang river. It has a main span of 926m and side spans of 275m, making it the third longest cable stayed bridge in the world. DLT were awarded the sub-contract by Second Highway Engineering Bureau to design a pair of 280 tonne capacity deck erection gantries to erect steel orthotropic deck segments weighing up to 369 tonnes each on one half of the main span.

Read more»

The other half of the deck was erected by Second Navigation re-using the deck erection gantries we supplied to them for the Sutong Bridge and the Shanghai Yantze Bridge

The Shanghai Yangtze cable stayed bridge carries both road and rail traffic and has a main span of 730 m that crosses the navigational channel along the link between Shanghai and Chongming Island. DLT were awarded the sub-contract by Second Navigational Engineering Bureau to provide site supervision during erection of bridge deck units. Modified DLT deck erection gantries from the Sutong Bridge project were used to erect the 46 No steel orthotropic deck segments, each weighing up to 387 tonnes, from Jan-June 2008.

Read more»

The A34 Wolvercote viaduct in the UK carries a 4 lane highway across a river, a railway line and the A40. To minimise disruption to traffic a new east carriageway was constructed alongside the existing 4 lane viaduct, followed by demolition of the old east carriageway structure and sideways sliding of the new structure across into final position. DLT were contracted by main contractor Costain Limited to design, supply and operate a hydraulic lifting and skidding system to move the 254m long, 4920 tonne new east carriageway the 16.6m from its construction position into final position on 8 parallel skidding tracks. Skidding, jack down and re-opening of the viaduct took place in a 18 hour overnight road and rail possession using our DL-SU350 bridge sliding system in March 2010.

Read more»

The Port Eglinton Viaduct carries a new 6 lane section of the M74 motorway over the West Coast Mainline railway in Glasgow, Scotland. It has a main span of 138m and a total length of 750m. A 200m length of each carriageway structure, weighing over 4000 tonnes, was launched 170m across the railway. The structures was moved by back-to-back 418t pulling and restraining strand jacks operating on a continuous cable running from one end of the launched structure to the other.

Read more»

The Xihoumen suspension bridge crosses the Xihoumen straight between the islands of Jintang and Cezi. It forms one part of a chain of bridges that link Zhoushan island to Ningbo, on the Chinese mainland to the south of Shanghai. It has a main span of 1650m and was the second longest suspension bridge in the world when completed. DLT were the designers and suppliers of the deck erection gantries, which were originally used on the Runyang Bridge Read more» and were modified for this project which had a different main cable spacing and diameter. 119 steel deck segments were erected with these gantries. Maximum lift weight was 370 tonnes. DLT also provided site supervision for the operation and maintenance of the gantries

The award wining Infinity footbridge is a 2-span tied arch crossing the river Tees in Stockton, England. Main span is 120m, side span is 60m. The arches are steel box sections and the deck is made from precast concrete segments that are post tensioned together to form the arch ties. DLT provided expert advice to the designers on erection methods and details for fabrication and buildability and provided full erection engineering to the contractor, including stage by stage analysis, aerodynamic response analysis and detailed design of all temporary works.

Read more»

With a main span of 1088m the Sutong Cable stayed bridge was the longest span cable stayed bridge in the world when completed. DLT were sub-contractors to 2nd Navigation Engineering Bureau for the design, supply and operation of the eight deck erection gantries that were used to erect the 84 No steel orthotropic deck segments, each weighing up to 450 tonnes, between 9th November 2006 and 9th June 2007.

Read more»

These gantries have since been used to erect the decks on two further bridges in China, the shanghai-Yangtze cable stayed bridge and the E-Dong cable stayed bridge.

On the Sutong bridge, we were also responsible for lowering of a 3050 tonne caisson.

Read more»

DLT were responsible for the detailed erection engineering, including detailed design of all temporary works and the cable system for this self anchored suspension bridge with a main span of 92.3m. The bridge was completed by a local contractor in May 2007.

Read more»

DLT were the sub-contractors for the erection of the three steel deck units forming the main 108m span of this multi-span box girder bridge. Two 2.5m long concrete / steel transition pieces, each weighing 100 tonnes, were erected first. This was followed by the erection of the main 103m long steel centre section weighing 1325te. The three lifts took place in May 2006

Read more»

At over 3km long and with two cable stay spans of 300m, this project provided many engineering challenges. The steel box girder deck for the 60m approach spans was launched in pre-assembled units of up to 2413 tonnes. The steel box girder deck of the two cable stay main spans was erected by balanced cantilever in 250 tonne segments using specially designed deck erection gantries. DLT were responsible for supply and operation of the strand jack systems for launching of the approach spans and for lifting and skidding of the main span deck units.

Read more»

DLT/FNP JV acted as advisors to the Client on key technical issues regarding the design and construction of the central tower on this 3 tower, 2x1080m span, suspension bridge. Our work included advising on the rigidity of the four leg tower, the risk of main cable slip over the tower, bridge articulation, use of hydraulic dampers and movement limiting devices and seismic analysis and design.

The ChaoTianMen arch bridge crosses the Yangtze river in the city of Chongqin in South West China. It has a tied arch main span of 552m with continuous side spans of 190m, and was designed to resemble the Sydney Harbour Bridge, completed by Dorman Long and Co. in 1932. DLT acted as consultant to the main contractor, 2nd Navigation Engineering Bureau and were responsible for developing and detailing the construction method to be used. On completion this was the longest arch span in the world.

DLT were sub-contractors for erection of the 24 No. 700 tonne steel deck units, which were erected in 2003 using a system of computer controlled strand jacks. The deck units were delivered directly to the bridge site by ship and lifted into final position using 4 No 290 tonne capacity strand jacks mounted on the deck units. DLT were also responsible for detailed erection engineering of the main cables, deck hangers and steel orthotropic deck.

Read more»

DLT were sub-contractors for design, supply and operation of strand jack and climbing jack systems for vertical lifting and horizontal skidding operations required to replace the existing railway over bridges with a new six lane composite bridge. DLT are also responsible for conceptual and detailed design of all construction methods, all of which took place within limited railway possessions.

Read more»

DLT were responsible for the design of the superstructure, as an alternative to the client's design, detailed design of the erection methods for all elements of the deck and for supply and operation of the strand jacking systems used to launch the deck into final position.

Read more»

DLT were responsible for the design, supply and commissioning of 4 No 370 tonne capacity deck erection gantries for this 1490m main span suspension bridge. These gantries were designed to walk the main cables and work in pairs to erect steel deck units weighing up to 470 tonnes each. The gantries were able to be self erected onto the main cables and can be easily adapted for future projects with different cable centres and diameter.

Read more»

DLT were responsible for the permanent works design and erection engineering for this landmark structure in the centre of Khartoum. The bridge has a main span of 210m and was designed for construction by local labour.

Read more»

DLT were responsible for the conceptual and detailed design of both of these bridges, which cross the river Nile in Khartoum. Both bridges were designed as a series of approximately 40m span concrete decks on reinforced concrete piers founded on piled foundations into the river bed. The decks were constructed from simply supported precast, post-tensioned T girders with a continuous reinforced concrete slab.

DLT were responsible for erection engineering of the bridge steel structure, involving off site assembly of the 3000 tonne main span, transport to site and lifting in one piece into final position using 8 No 500 tonne capacity strand jacks.

Read more»

DLT were responsible for detailed erection engineering, equipment supply and site supervision for deck erection on this 1385m main span suspension bridge.

Read more»

DLT were responsible for detailed erection engineering, equipment supply and site supervision for deck erection on this 1377m main span suspension bridge.

Read more»

DLT were responsible for the design, supply and operation of a 800 tonne capacity climbing jack system for the lifting and lowering of temporary formwork support trusses for the construction of 80m long in-situ post tensioned concrete approach spans.

Read more»

DLT were responsible for value engineering of the permanent strengthening and widening works and conceptual and detailed design of all erection and demolition methods and related temporary works for carrying out this upgrade to the existing 335m span suspension bridge.

Read more»

DLT were responsible for supply and operation of a strand jacking system to carry out replacement of the complete bridge deck in 54 sections, each within a 10 hour overnight closure of the bridge. 4 No DL-S60 strand jacks (plus 2 No spare jacks) with power and control system for a lifting speed of 60 metres per hour were supplied to the main contractor, American Bridge.

DLT were responsible for the conceptual and detailed design of the temporary erection gantries required to construct the bridge. Eight No 418 tonne capacity strand jacks mounted at the top of the two gantries were used to lift the bridge to approximately 2.4m above final level to allow installation of the pylons beneath.

Read more»

DLT were responsible for the design of the Popolopen Creek Footbridge to create an economic and aesthetically pleasing river crossing of 140m main span on the Appalachian Trail in Bear Mountain Park, Fort Montgomery, NY. The bridge is a hybrid of a suspension bridge and a truss bridge and was designed for ease of construction.

Read more»

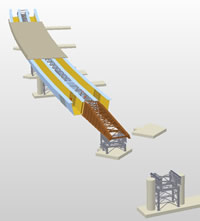

DLT were responsible for the design and supply two FST (floating slab) handling gantries that would lift the track slabs off delivery carriages, two at a time, and lay them onto final position. Each floating slab weighs up to 6 tonnes.

Read more»

In 2014 we designed and supplied a 5,000 tonne lifting capacity jacking tower system to China National Petroleum (CNPCC) for use in the erection of heavy petrochemical vessels. The MYQ5000 jacking tower system is able to self-erect and self-dismantle, and is also able to move with the vessel after lifting. The MYQ5000 was successfully load tested in December 2014 and is expected to complete its first project in China in 2015.

Read more»

DLT supplied an eight jack 3600 MT capacity weighing system to PTSC Vietnam in April 2014. The weighing system incorporates load cells for a load accuracy of 0.5% and has a central computer control system for synchronised lifting and lowering of the load and for data logging throughout the weighing operation.

Read more»

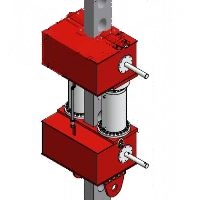

Sinopec Tenth Construction Company have placed a contract with DLT for the supply of a 7200 tonne lifting capacity jacking tower system, for use in the erection of heavy petrochemical vessels. The tower system uses DL-CP600 pinned climbing jacks for lifting, which climb up bars fitted to the inside faces of the towers. The tower system will be delivered in 2014

Read more»

DLT supplied two complete float over jacking systems to Swiber Offshore Construction for the offshore installation of platforms weighing up to 13,400 tonnes in the ONGC B-193 process complex in the Arabian Sea.

Read more»

DLT supplied a 2 x 1000 te capacity (push/pull) jacking system to Nippon Steel in Japan for use on their offshore jacket installation barge that was launched in 2012. The jacking system comprises 2 No DL-GP1000 gripper jacks and was designed to walk along a purpose designed skid track. It will be used for load out of jackets onto the installation barge and for launching of the jackets from the barge at the installation site

Read more»

DLT were sub-contracted to design, supply and operate a skidding and jacking system to incrementally erect a 26m x 22m x 140m high 2800 tonne jacket structure. The jacket was erected in 8 sections, weighing up to 660 tonnes each using our DL-TS3000 tower system.

Read more»

DLT have supplied many strand jack systems for the installation and replacement of thruster units weighing up to 50 tonnes on drilling ships and floating platforms. Strand jacks provide a compact and cost effective solution for handling heavy thruster units and we have also developed a system of modular power packs and jacks that can be taken through bulkhead doors into the thruster room. Our client list for this work includes Stenna Drilling, Jurong shipyard, Daewoo shipyard, Resource Rigging, Sea Drill, Frontier Drilling, Larsen Oil and Gas, Noble Corporation, Wartsila, Transocean and Napro Services.

Read more»

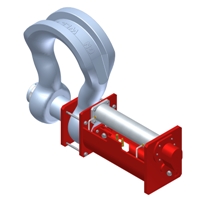

DLT were sub-contracted to provide a strand jacking system to raise a mooring yoke to release an FSO vessel from its mooring buoy where it had be located for 20 years. The original 1000te capacity long stroke ram used to install the yoke was unserviceable. DLT engineered a system using 2No DL-S418 strand jacks mounted on a T-frame attached to the FSO using the existing long stroke ram mounting point. The jacks were powered by a DL-L114/4/D diesel engine operated hydraulic power pack.

DLT were sub-contracted to side shift and launch 2 No 3600 tonne pontoon units at the Jurong Shipyard, Singapore, in May and June 2007 for the Sea Drill floating platform No 8. The first pontoon was launched 125m down a 6 degree slope into the water in May. The second pontoon was side shifted 100m into position for launching and then launched down the same slope as the fist pontoon. The pontoons were supported on inflated air bags for all these operations and moved using 2 no DL-S185 strand jacks and 2 No DL-L30F/1/350/120/E power packs for a launching speed of 17 m/hour, controlled using our DL-P40 computer control system

DLT were sub-contracted to assist in the installation of a FSO mooring line system 32 km offshore in the Corocoro Oil Field, Venezuela. DLT designed and supplied the strand jack tensioning system to pull pairs of mooring lines toward one another causing their anchors to plough into the sea bed and subsequently test load the mooring lines to a 700te tension.

Read more»

DLT were responsible for the installation of a number of FPSO mooring yoke and pendulum structures weighing up to 1040 tonnes using strand jacks for lifting and final alignment to make the permanent connections. Our client for these operations were SMOE and Keppel Singmarine in Singapore, with work being carried out in Singapore and Azerbaijan.

Read more»

DLT were responsible for the design, supply and site supervision for a modular jacking tower system that has so far been used to erect 58 vessels weighing up to 1,557 tonnes and up to 114.5m long.

Read more»

DLT were responsible for the conceptual and detailed design of this 2500 tonne lifting capacity modular strand jack tower system, specifically designed for the Chinese refinery construction market in 2002. The tower system is owned and operated by the No 4 Construction company of SINOPEC and has many features including self-erection, and luffing under full load.

Read more»

DLT were responsible for the design, supply and site supervision for a strand jack system to load out a 14,500 tonne FPSO pontoon onto a delivery ship, for main contractor Hyundai. The deck was moved 125 metres using four 580 tonne capacity strand jacks.

DLT were responsible for the design of a 2300 tonne lifting capacity lifting gantry for handling cut sections of the Brent Spar as it was decommissioned in a Norwegian fjord in 1999. The gantry used 4 No 580 tonne capacity strand jacks for lifting and a gripper jack system for longitudinal movement over the decommissioning barge. The legs and cross beams of the gantry structure were made from a proprietary tower system which were connected and braced using purpose designed steelwork.

In June 2015 Lift and Shift India installed their first generator using a 540 tonne capacity modular gantry designed and supplied by DLT. The gantry is modular to accommodate the geometry of each site and incorporates folding strand jacks to reduce the headroom requirement as the generator is moved into the turbine hall and under the overhead crane rail. The gantry is able to lift, rotate and move the generator into final position and incorporates both transverse and longitudinal movement systems to allow the generator to be set accurately onto its foundations.

Read more»

In 2010 DLT supplied a 370 tonne capacity strand jack lifting system to BHEL Western Division in India for use in the construction of power stations. The system comprises 2 No DL-S185 strand jacks powered by 2 No DL-L40/1/300/E electrically powered hydraulic power packs for a lifting speed of 20 m/hr and controlled using our DL-M2 pendant control system. The first steam drum was lifted in November 2010.

Read more»

In November 2010 Rigging International used 2 No DL-S418 strand jacks to replace a steam generator in the SONGS nuclear power plant in California. The lifting system comprised 2 No DL-S418 strand jacks powered by 1 No DL-L60/4/300/D diesel powered hydraulic power pack for a lifting speed of 14 m/hr and controlled using our DL-P40 computer control system. The operation took place adjacent to a live nuclear reactor in an environment with very high electrical magnetic interference. Our DL-P40 computer control system was approved for use in this environment following a successful 24 hour continuous running test on the site.

DLT were sub-contractors for installation of a new 40.75m high 3115 tonne furnace in Taiwan. Our scope included full engineering of all temporary works required together with supply of jacking equipment and site labour to carry out the work. The blast furnace was delivered to the site in 8 segments, weighing up to 477 tonnes each, which were lifted and skidded into the furnace house before being jacked vertically and aligned for welding. These operations were carried out using a mix of strand jacks and climbing jacks.

Read more»

The BARD 1 wind farm is located in the North Sea and has a total of 80 wind turbines producing up to 400 MW which is connected into the German extra-high-voltage grid via a 125km long submarine cable. DLT supplied and operated a 16 x DL-S588 computer controlled strand jack system for the self-installation of the central transformer and accommodation platform. The strand jack system was used to suspend the 3,500 tonne jacket from the floating platform during sea transport, then to lower the jacket down onto the sea bed, and finally to lift the 3,320 tonne platform up out of the sea into final operating position where it was then structurally connected to the jacket.

Read more»

DLT have provided strand jack systems and site supervision to Rigging International for lifting and installation of a number of steam drums weighing up to 380 te and lifted up to 65 m. The strand jack system supplied comprises 2 No DL-S418 strand jacks and a DL-L60F/4/350/D diesel powered hydraulic power pack, with a combined lifting capacity of 836 tonnes and a lift speed of 15 m/hour

DLT were employed by Odebrecht to supply equipment and site supervision to install a water distribution pipe which was required to pass over one of Dominican's many mountains. DLT's equipment and supervisors assisted in the installation of the pipe, pulling a total of 78 sections, from 10 different locations using DLT strand jacks. The maximum pull was 132 tonnes, and the longest pull was 157m.

Read more»

DLT were responsible fore the design, supply and operation of a 60 tonne capacity gantry to replace 2 No 60 tonne heat exchangers from deep within a steel framed structure on PT Peni's site in Indonesia. Use of these purpose designed gantries in place of conventional cranes avoided the need to extensively dismantle the steel structure to gain access to the vessels, saving time and money.

DLT were awarded two contracts from Victor Buyck (Malaysia) on this project. The first was to supply a 4 x DL-S185 strand jack system to lift 2 No 200 tonne 60 m long mega trusses that are used to support the roof over the main hall of the convention centre.

Read more»

The second was for the design and supply of a synchronised jacking system to open and close 2 No 270 tonne angel wings located on the roof.

Read more»

DLT supplied a 48 x 98 tonne computer controlled strand jack system to Protende in Brazil for the erection of a cable net roof structure on the Brasilia stadium, constructed to host the 2014 world cup.

Read more»

DLT were sub-contractors for the erection of the 940 tonne steel roof structure for the new 2000 seat theatre as part of the Venetian Development in Macau. Our scope included erection engineering, equipment rental and site operation. The roof trusses were assembled on site at ground level and then lifted into position using a climbing jack system. The roof trusses were erected in 3 separate lifts, each weighing up to 400 tonne.

Read more»

DLT were sub-contractors to China State-Leighton JV for the lifting of the 3,520 tonne pre-assembled steel roof. The roof was lifted 30m using 8 No DL-S418 strand jacks mounted on 4 No 40m high DL-TS3000 free standing towers and 6 No DL-S185 strand jacks mounted on the permanent concrete columns. All jacks were monitored, synchronised and controlled by a single operator using our DL-P40 computer control system

DLT were responsible for the detailed erection engineering for the 18,500 tonne steel roof structure of the new main core terminal building, and for a 1000 tonne air traffic control tower. Both were fabricated off-site and erected on-site using strand jack lifting systems. The roof box girders, purlins and cladding to the core terminal building roof were erected in 6 No 2,000 tonne lifts. The control tower was pre-assembled off-site into 7 fully complete modules and then assembled on-site using a unique vertical jacking technique.

Read more»

DLT were responsible for the detailed erection engineering for the 26,000 tonnes of structural steel, including stands, cable suspended roof and main arch structures. The 1,490 tonne main arch was assembled flat and rolled up into position using strand jacks. We were responsible for engineering and supervising this operation.

Read more»

DLT were responsible for erection engineering, heavy lifting equipment supply and operation for the erection of an 8000 tonne prefabricated roof structure and a 5,500 tonne link bridge. The roof structure was fabricated and assembled in the Philippines into modules weighing up to 460 tonnes each, which were then shipped to the site for lifting and skidding into final position. The link bridge was erected piece small by a stiff leg derrick mounted on a purpose made skid track. Access to this part of the site was very restricted, requiring the stiff leg derrick to construct its own skid track and then work backwards along the skid track to erect the permanent works.

Read more»

DLT were responsible for the design, supply and operation of a strand jack lifting system together with associated erection engineering to lift 2 No pre-assembled roof sections, each weighing over 1000 tonnes. Each section of roof was lifted with 9 No DL-S185 strand jacks. Temporary works for the lift comprised 3 No 300 tonne capacity jacking towers, plan bracing to stabilise the roof and a guide track against the concrete core structure.

Read more»

DLT were responsible for the detailed erection engineering for the lifting by strand jacks of an 800 tonne roof truss for this aircraft maintenance hangar at Heathrow Airport. The roof structure was assembled at ground level and then lifted using strand jacks mounted on the top of the permanent columns, which were stabilised by rented proprietary towers that were anchored down to the permanent foundations.

DLT were responsible for the design, supply and operation of a strand jack heavy lifting and horizontal skidding system for the erection of two 1100 tonne pre-assembled link bridges in Hong Kong for main contractor, Gammon-Skanska.

The roof to this convention centre is constructed from a complex series of curved V shaped steel trusses that work with a plan tie system in the finished state to provide a rigid and stable structure. To reduce the roof erection cost and programme, the roof was assembled in fully clad panels adjacent to the site and erected onto temporary supports within the building. We were responsible for the detailed erection engineering of the roof, including all temporary supports and stability bracing, which was required to withstand cyclone wind loads at any erection stage.

DLT were responsible for detailed connection design and erection engineering of the 6,600 tonnes of steel frame to this 16 storey office block. This included heavy lifting of a 650 tonne module which was built on a lower floor and then raised 30m to the 16th floor. DLT were also responsible for supply and operation of the strand jack system to carry out this lift, using 4 No DL-S185 strand jacks.

We are a multidisciplinary team of engineers working on the design, development, manufacture, commissioning and site operation of the latest equipment & methods for the modular construction of bridges, offshore structures, large buildings, power stations and other structures where there is the need to erect heavy modules. On most projects we work with the client to determine the best method of construction and then provide the complete service of construction engineering, supply of equipment and site supervision. Our design and construction team is a mix of civil, structural, mechanical, electrical and control systems engineers working from our offices in the UK, China and India.

If you have a passion for engineering and wish to develop your career with like minded people then we would love to hear from you. We offer a good package & benefits, opportunities for travel, training for professional development and a stimulating working environment. You will be working with some of the best engineers in the business.

If you would like to join our team then please send your CV with covering email to careers@dormanlong.com. We welcome quality applications at all times.

For general enquiries please contact enquiries@dormanlong.com

The Charles Parker Building, Midland Road,

Higham Ferrers, Northamptonshire, NN10 8DN,

United Kingdom

Tel. +44 (0)1933 319133

Contact: Mr David Dyer. david.dyer@dormanlong.com

UK Northern Office:

Whessoe Technology Centre

Morton Palms, Darlington

Co Durham, DL1 4WB, United Kingdom

Tel. +44 (0)1325 390010

Contact: Mr Chris Wilkinson. chris.wilkinson@dormanlong.com

Dorman Long Technology (Shanghai) Co. Ltd

19D Yu Jia Building, 1336 Huashan Road

Changning District, Shanghai 200052

Tel. +86 (0) 21 31756400

Contact: Mr Hongyi Tao. hongyi.tao@dormanlong.com

India Office:

Dorman Long Technology India Pvt. Ltd.

208, Tower A, Spazedge Commercial Complex

Sector - 47,

Sohna Road, Gurgaon (Nr New Delhi)

Pin-122018, Haryana, India.

Tel. +91 124 4270791

Mr Amanpreet Singh Lamba. aman.lamba@dormanlong.com